Low MOQ for Precision Steel Tube Galvanized channel steel – Star Good Steel

Low MOQ for Precision Steel Tube Galvanized channel steel – Star Good Steel Detail:

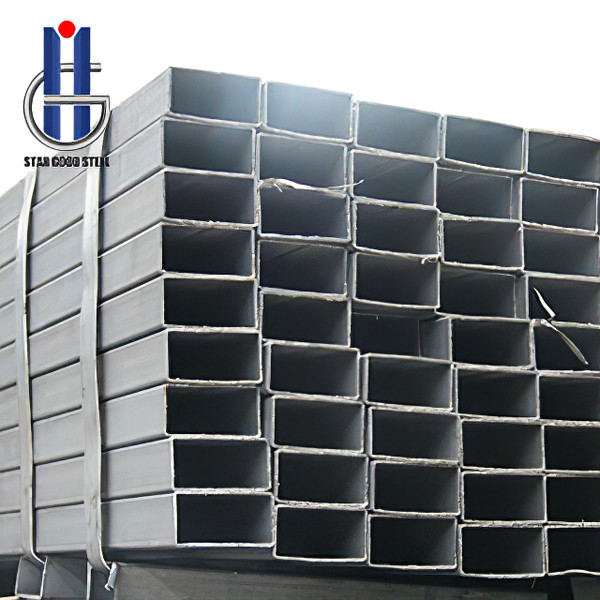

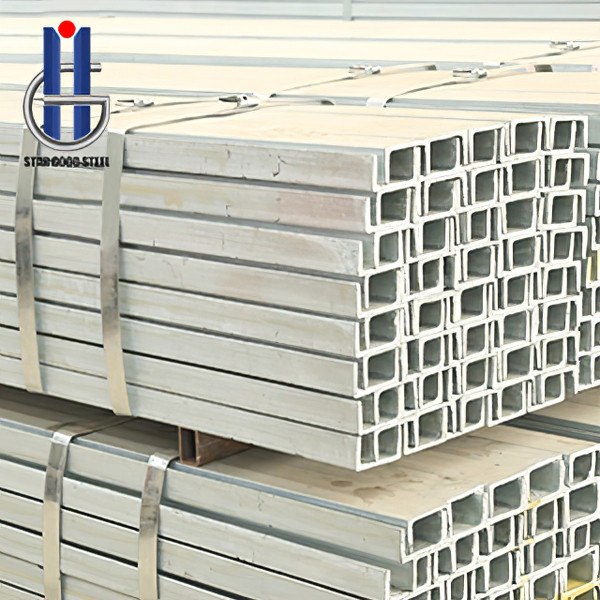

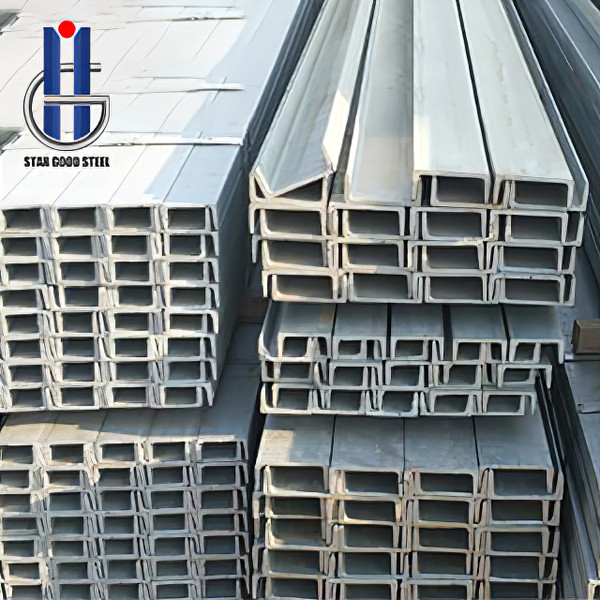

| Item | Galvanized channel steel |

| Introduction | Galvanized channel steel is an effective metal anti-corrosion method, mainly used in metal structure facilities in various industries. Hot-dip galvanized channel steel can be divided into hot-dip galvanized channel steel and hot-blow galvanized channel steel according to different galvanizing processes. The derusted steel parts are immersed in molten zinc solution at about 440~460℃ to make the steel A zinc layer is attached to the surface of the component to achieve the purpose of corrosion protection. Among various coating methods for protecting steel substrates, hot-dip galvanizing is a very good one. It is when the zinc is in a liquid state, and after quite complex physical and chemical actions, not only a thicker pure zinc layer is plated on the steel, but also a zinc-iron alloy layer is formed. This plating method not only has the corrosion resistance characteristics of electro-galvanization, but also has a zinc-iron alloy layer. It also has strong corrosion resistance unmatched by electro-galvanizing. Therefore, this plating method is particularly suitable for a variety of strong acid, alkali mist and other strong corrosive environments. |

| Standard | ASTM, DIN, ISO, EN, JIS, GB, etc. |

| Material | A53, A283-D , A135-A , A53-A, A106-A, A179-C, A214-C, A192, A226, A315-B, A53-B, A106-B, A178-C, A210-A-1, A210-C, A333-1.6, A333-7.9, A333-3.4, A333-8, A334-8, A335-P1, A369-FP1, A250-T1, A209-T1, A335-P2, A369-FP2, A199-T11, A213-T11, A335-P22, A369-FP22, A199-T22, A213-T22, A213-T5, A335-P9, A369-FP9, A199-T9, A213-T9,etc. |

| Size | 80x40x2.0mm-380x110x4.0mm, or as requiredthickness: 4.5mm-12.5mm, or as required

Length: 1m-12m, or other lengths required |

| Surface | Galvanized or as request. |

| Application | With the development of industry and agriculture, the scope of application of galvanized channel steel has also expanded accordingly. Therefore, hot-dip galvanized products are used in construction (such as: glass curtain walls, power towers, communication grids, water and gas transmission, wire casing, scaffolding, houses, etc.), bridges, transportation; industry (such as chemical equipment, petroleum processing, ocean exploration , Metal structures, power transmission, shipbuilding, etc.); agriculture (such as: sprinkler irrigation, greenhouses), etc., have been widely used in recent years. As hot-dip galvanized products have the characteristics of beautiful appearance and good corrosion resistance, their applications are becoming more and more extensive. |

| Package | Standard export package, or as required. |

| Price term | Ex-work, FOB, CIF, CFR, etc. |

| Payment | T/T, L/C, Western Union, etc. |

| Certificates | ISO, SGS, BV. |

Customer evaluation

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

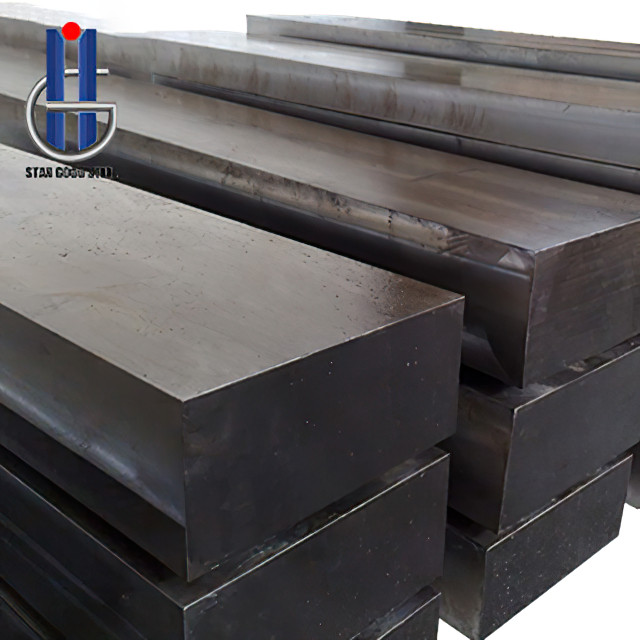

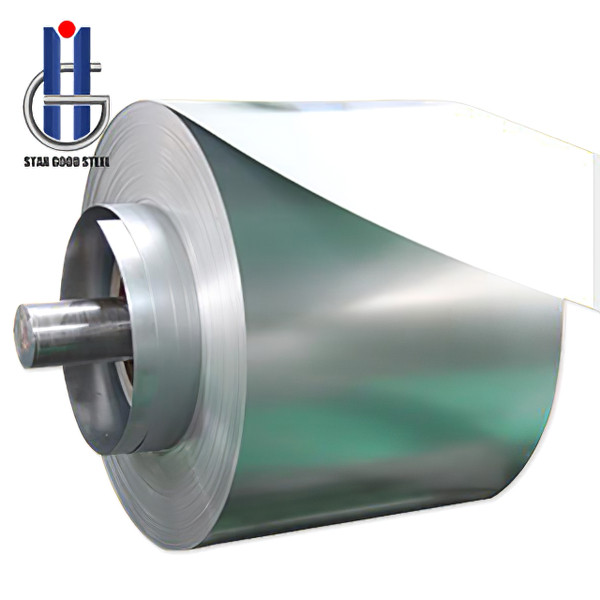

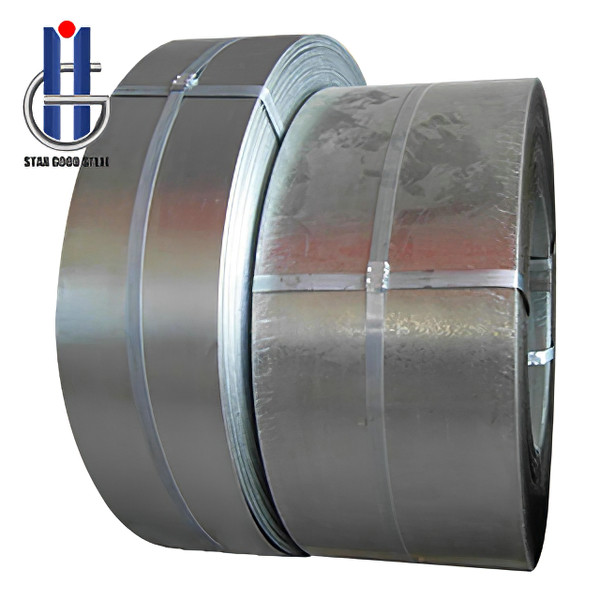

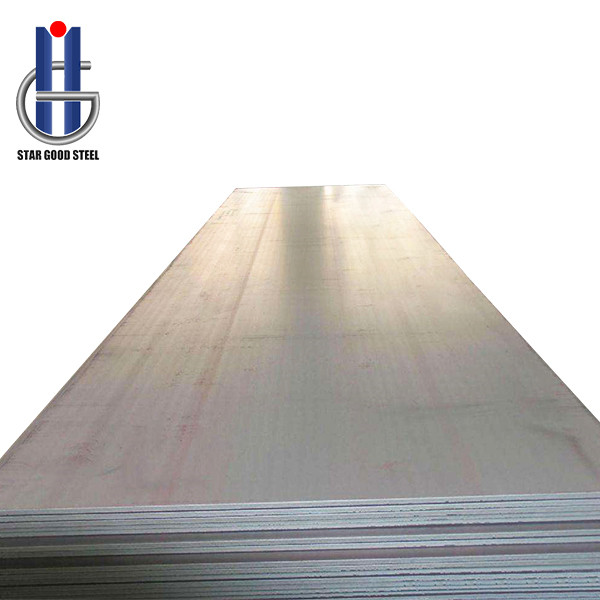

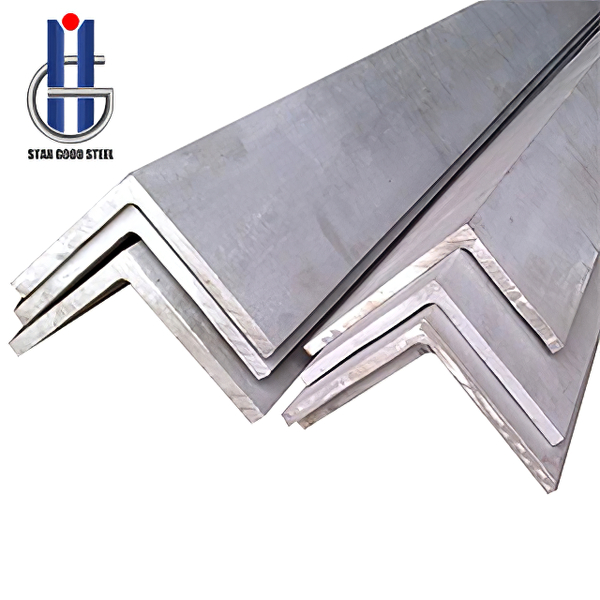

Product detail pictures:

Related Product Guide:

During the past few years, our business absorbed and digested state-of-the-art technologies the two at home and abroad. Meanwhile, our firm staffs a group of experts devoted to your development of Low MOQ for Precision Steel Tube Galvanized channel steel – Star Good Steel , The product will supply to all over the world, such as: Benin, South Korea, Slovakia, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.

Write your message here and send it to us