Reasonable price Galvanized Angles Die steel plate – Star Good Steel

Reasonable price Galvanized Angles Die steel plate – Star Good Steel Detail:

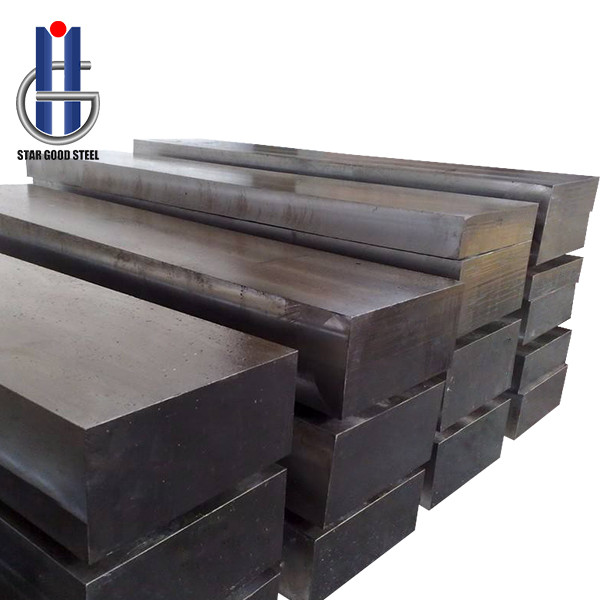

| Item | Die steel plate |

| Introduction | Die steel is used to make cold die, hot forging die, die casting die and other steel types. Moulds are the main processing tools for manufacturing parts in machinery manufacturing, radio instruments, motors, electrical appliances and other industrial sectors. The quality of the mold directly affects the quality of the pressure processing technology, the accuracy of the product, and the production cost. The quality and service life of the mold are mainly affected by the mold material and heat treatment, in addition to the reasonable structure design and processing accuracy. Die steel can be roughly divided into three types: cold-rolled die steel, hot-rolled die steel and plastic die steel, which are used for forging, stamping, cutting, and die-casting. Due to the different purposes of various molds and complex working conditions, the steel used for molds should have high hardness, strength, wear resistance, sufficient toughness, and high hardenability and hardenability according to the working conditions of the mold made by it. Hardness and other technological properties. Due to the different uses and complex working conditions of this type, the performance requirements for mold steel are also different. |

| Standard | ASTM, DIN, ISO, EN, JIS, GB, etc. |

| Material | A53, A283-D, A135-A, A53-A, A106-A, A179-C, A214-C, A192, A226, A315-B, A53-B, A106-B, A178-C, A210-A-1, A210-C, A333-1.6, A333-7.9, A333-3.4, A333-8, A334-8, A335-P1, A369-FP1, A250-T1, A209-T1, A335-P2, A369-FP2, A199-T11, A213-T11, A335-P22, A369-FP22, A199-T22, A213-T22, A213-T5, A335-P9, A369-FP9, A199-T9, A213-T9, 523M15, En46, 150M28, 150M19, 527A19, 530A30, etc. |

| Size | Length: 1m-12m, or as requiredWidth: 0.6m-3m, or as required

Thickness: 10mm-500mm, or as required |

| Surface | Black surface, Grinding, Polishing, Milling, Machined, etc. |

| Application | When processing molds, because molds have a wide range of uses and the working conditions of various molds are very different, there is a wide range of materials for manufacturing molds, and mold steel is the most widely used mold material. From general carbon structural steel, carbon tool steel, alloy structural steel, alloy tool steel, spring steel, high-speed tool steel, stainless heat-resistant steel to maraging steel and powder high-speed steel that meet the needs of special molds, Powder high-alloy die steel, etc. Die steel can generally be divided into three categories: cold work die steel, hot work die steel and plastic die steel. |

| Package | Standard export package, or as required. |

| Price term | Ex-work, FOB, CIF, CFR, etc. |

| Payment | T/T, L/C, Western Union, etc. |

| Certificates | ISO, SGS, BV. |

Customer evaluation

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.

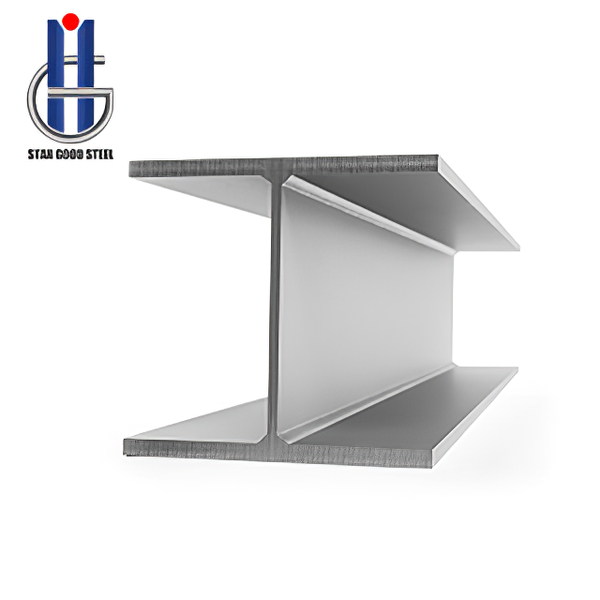

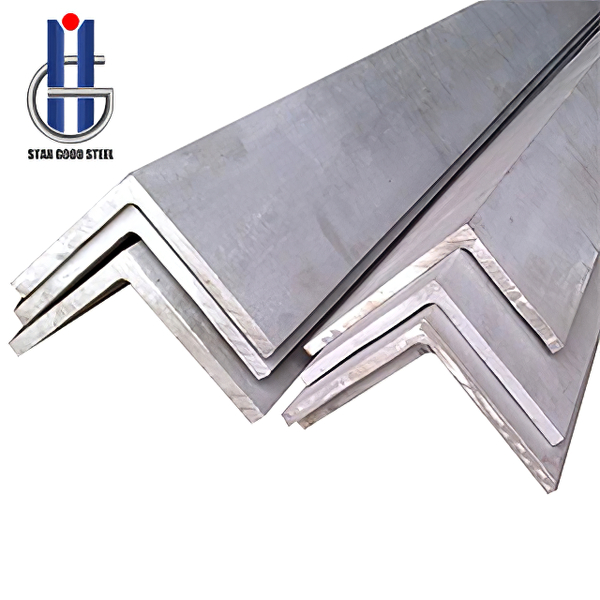

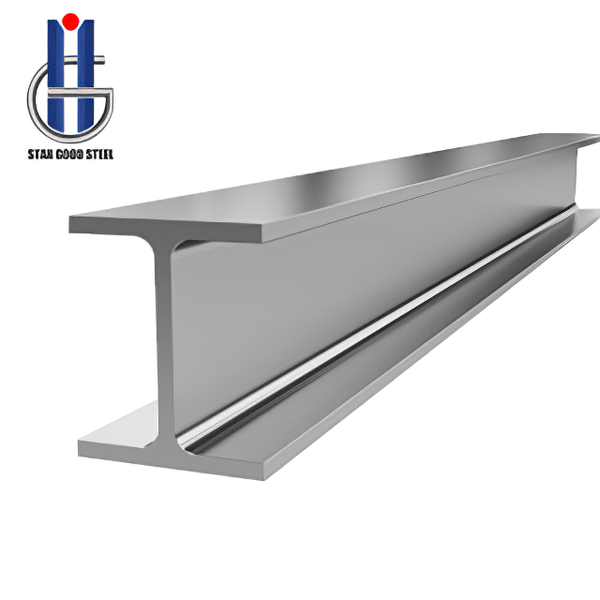

Product detail pictures:

Related Product Guide:

We now have our own gross sales team, style and design workforce, technical crew, QC workforce and package group. We now have strict quality manage procedures for each system. Also, all of our workers are experienced in printing industry for Reasonable price Galvanized Angles Die steel plate – Star Good Steel , The product will supply to all over the world, such as: Korea, Malaysia, Namibia, We sincerely hope to cooperate with customers all over the world, if you would like to have more information, make sure you kindly contact us, we have been looking forward to building up a great business relationship with you.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.

Write your message here and send it to us